3mm Mini Laparoscopic Port

Collaboration with Children’s Hospital Colorado to create a novel surgical port

Download a copy of the poster here

Motivation

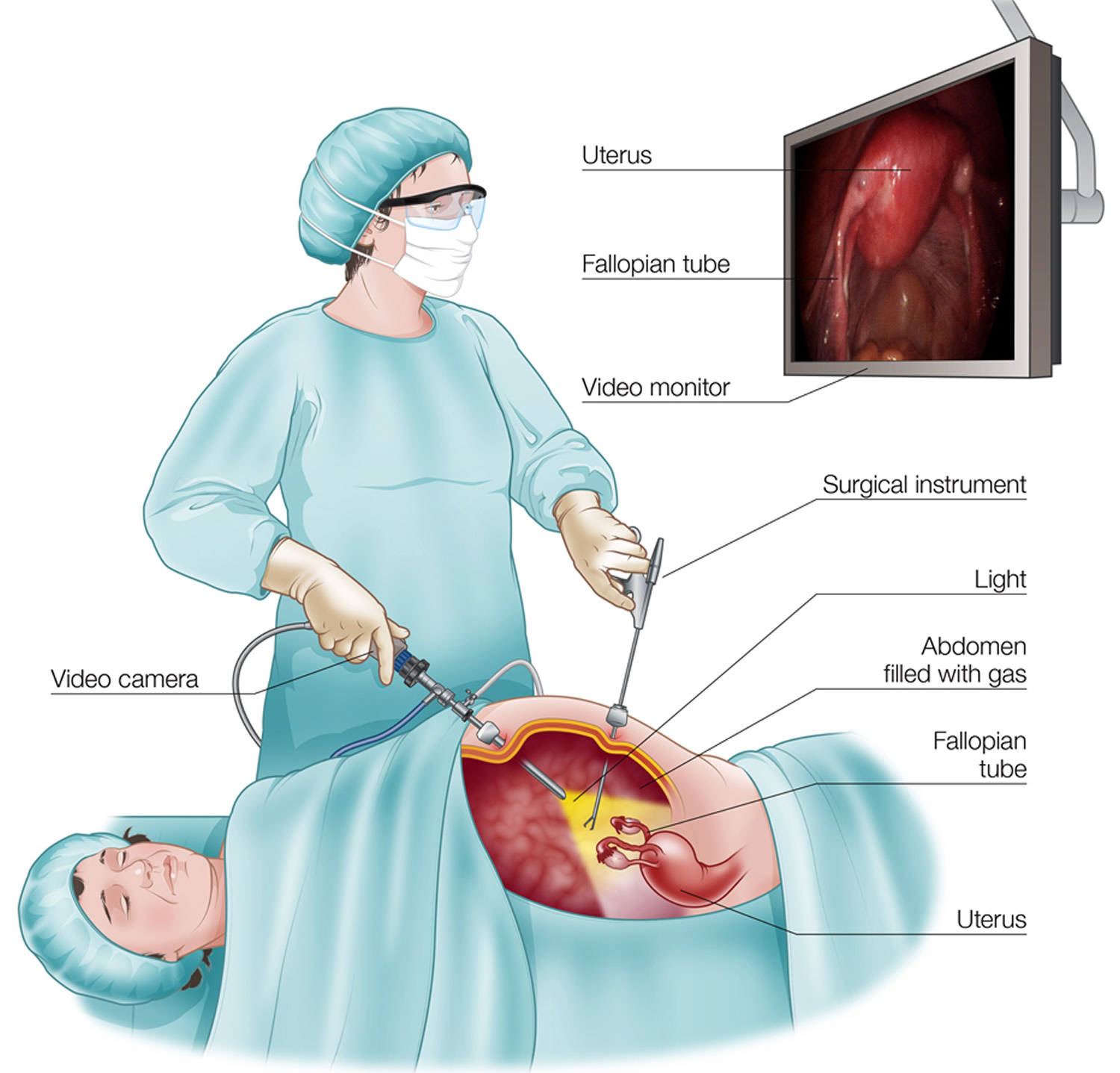

Laparoscopic surgery is a type of minimally-invasive surgery whereby incisions are made into the umbilicus (the belly button) and then several other incisions are made near this first incision. The umbilicus incision is made first, and then a 5 mm camera and light are inserted. The abdominal cavity is then insufflated, which is the process whereby gas (usually carbon dioxide) is pumped into the abdominal cavity to allow for easier manipulation of surgical instruments.

Core to all of these procedures is the laparoscopic port, one of which can be seen below:

These ports come in various ranges, such as 5 mm, 10 mm, and 12 mm. This number refers to the size of the instrument that can be used with the port itself, meaning that the diameter of a 10 mm port would be somewhere around 10.75 mm to allow for insertion and removal of 10 mm laparoscopic instruments.

Babies in the Neonatal Intensive Care Unit (NICU)

These ports work great for adults, when the thickness of the abdominal cavity is enough to keep the port in place and the patient is large enough that there is enough room to maneuver the laparoscopic tools without the surgical field getting too crowded. Both go completely out the window when working on babies in the NICU, which is where Colorado Children’s Hospital comes into the picture.

Our client for this project was a pediatric surgeon from Colorado Children’s Hospital, and one of the first things he told us was the size of the surgical field. It’s the size of a grapefruit. A grapefruit. This meant that every single piece of material we used had to be there for a purpose.

The Design Challenge

The design challenge consisted of two main issues: crowding of the surgical field and port dislodgement. The former arises from the incredibly small size of the surgical field, with the latter arising from the incredibly thin abdominal walls found in neonates.

Throughout the undergraduate engineering curriculum, it is drilled into each one of us to design the best thing possible. This isn’t a bad thing by itself. But one of the biggest lessons I learned at the beginning of this entire process was this:

The best design from a technical perspective isn’t always what the client wants.

My first design was the most unconventional. It was a weird gyroscope that had the laparoscopic tools go through it. The surgeon picked it up and was instantly confused. Was it the best design technically? Maybe, who knows. But that didn’t matter. What mattered was that there was zero intuition in the design and no empathy to the user. As we progressed throughout our design iterations, I made it a point to ensure that each design had a certain level of empathy towards the surgeon. We made sure that the top of the device was sculpted to feel great in the hand, specifically the hand shape the surgeon uses when inserting the instrument into the abdomen. Another important element of design was how our device interacted with the senses. During laparoscopic surgery, the surgeon is typically looking at a video feed, not always the instruments themselves. This means that the instrument needs to be able to tell the surgeon what is going on without the surgeon looking at it. To that end, we designed some tactile feedback into the device (specifically at the top) so that the surgeon can feel when all the pieces are locked properly.

A (Nearly) Blank Piece of Paper

One thing that is important to mention here: none of us on the team had any experience with the design or testing of medical devices. Most of us didn’t even know what laparoscopic surgery was, much less how to design an instrument that would be helpful for a surgeon who has already been performing these operations for years. On top of that, the surgeon came to us with a sketch that he had made on his dining room table. No specifications, no bill of materials. Nothing. Just a nearly blank piece of paper and an idea. Most of the other teams had clients that came to them with lists of specifications, other designs the company had tried, and usually a team of engineers. Not here. To be honest, that freedom and lightness allowed us as a team to create a design that was unique and one that each of us is proud of. It also let us see the entire product development process, which was unique. Unlike many other teams, we had to figure out what specifications we should hit. This was specifically helpful in helping me realize the importance of assumptions throughout the design process. It’s very easy to keep track of the technical specifications, but assumptions are what I found to cause many of the problems, and keeping track of them was a good way to categorize what problems might crop up in the future.

The Solution

The novelty in the design was that it features a large air channel towards the top which features a bumper that slides down, forcing the air into a reservoir below the abdominal wall that inflates a retention mechanism. Once the procedure has finished, the retaining mechanisms are removed, and the air moves back up the shaft of the port and the procedure is completed. This is shown in picture form in the poster download at the top of this page. One of the highlights of this project was the feedback from other surgeons at CU’s Engineering Projects Expo. Multiple surgeons with decades of experience held the port and commented on how familiar it felt and how it addressed many of their personal concerns when working on smaller patients.

Manufacturing

We used the FormLabs 3B stereolithography (SLA) 3D printer for all of our prototypes and designs. This was due to the need for extremely tight tolerances, making traditional methods such as machining or “regular” fused-deposition modeling (FDM) 3D printers too time-prohibitive, imprecise, or both. We elected to use the FormLabs Clear resin for a large part of the port’s body, and the FormLabs Flexible resin (50A durometer rating) for flexible areas of the device, such as those for sealing around laparoscopic instruments. The FormLabs Clear resin was found to be similar in material properties to the FDA-approved FormLabs resins, such as BioMed Durable.

Testing

Testing consisted of tensile testing and three-point bending, with the former conforming to ASTM D638-14 (Type IV) and the latter conforming to ASTM D790-15 (Procedure B). We also created custom testing procedures based on these standards that are more close to environments found in laparoscopic procedures.

Intellectual Property and Funding

The international patent application can be found here.

Initial seed funding provided by University of Colorado Anschutz School of Medicine under the SPARK Grant.

Citation

@online{gregory2024,

author = {Gregory, Josh},

title = {3mm {Mini} {Laparoscopic} {Port}},

date = {2024-05-02},

url = {https://joshgregory42.github.io/projects/senior_design/},

langid = {en}

}