About

Current Work

I recently completed my graduate studies at the University of Colorado Boulder studying Mechanical Engineering with a focus on artificial intelligence applied to biomedical imaging. I was a member of CU Boulder’s Biofluidics Laboratory (FlowLab), where I used computational fluid dynamics (CFD) to study blood clots and how strokes occur in the human body. The goal of this research is to model the blood clotting process much more accurately than previously done, ultimately to allow medical professionals to make better clinical decisions.

M.S. Thesis

My Master’s Thesis, while in mechanical engineering, sits at the intersection of a few different fields. Specifically biology, computer science, and mechanical engineering.

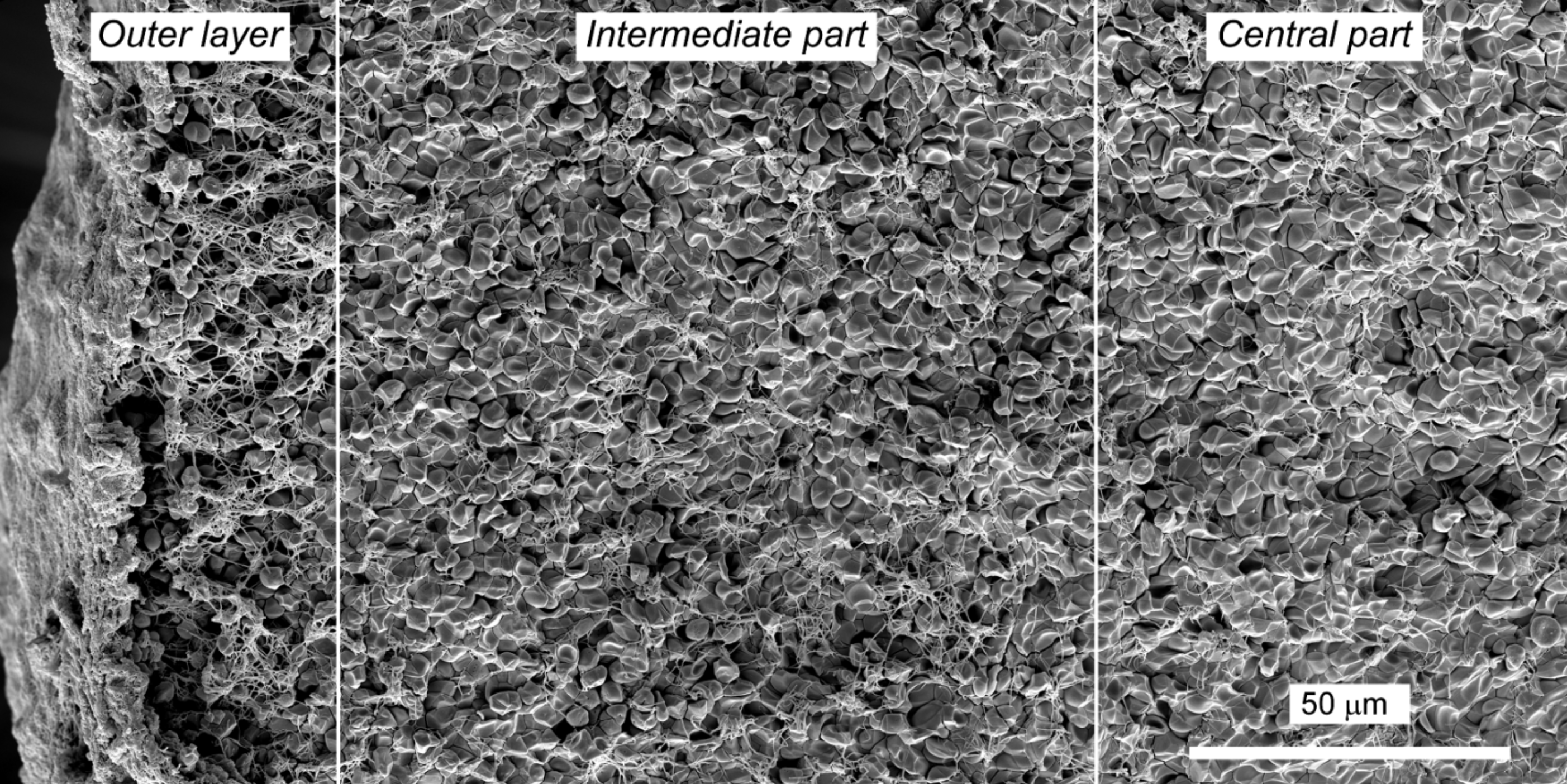

As shown in the figure above, blood clots are porous media. The current drug of choice for breaking up blood clots is tissue-type plasminogen activator (tPA). However, dosing such a drug becomes difficult when a clot (or multiple clots) exhibits varying blood perviousness due to its complex microstructure. My thesis aims to utilize deep learning to analyze imaging of blood clots and predict blood clot permeability, allowing clot-specific dosing of drugs like tPA.

Past Work

I have worked at corporations such as Collins Aerospace and the National Renewable Energy Laboratory (NREL). At Collins Aerospace, I aided senior engineers in testing prototype optical devices for future usage on both commercial and military aircraft. I used my knowledge of computer-aided design (CAD) and 3D printing to design and manufacture testing apparatuses that enabled rapid prototyping and characterization of the prototype optical devices. At NREL my work focused on additively-manufacturing microencapsulated phase-change materials (MEPCMs) for use in thermal batteries and heat exchangers.

After transferring to CU Boulder, I joined the liquid engine sub-team of CU’s Sounding Rocket Lab (SRL), where I ran the computational fluid dynamics (CFD) team simulating the nozzle and injector assemblies, specifically focusing on the mathematical models used to run the simulations.

At my previous institution, I was a member of Oregon State’s High Altitude Liquid Engine (HALE) team, where I ran multiphase CFD simulations on both the injector and nozzle assemblies using Oregon State’s supercomuter cluster to perform more detailed analyses.

I was also a member of the Oregon State College of Psychology’s CARVE Laboratory, where I worked on the software necessary to better understand the interaction between pedestrians and autonomous vehicles.

During high school, I wrote a paper where I derived a fundamental equation relating to rocket nozzle theory, which I then verified experimentally via computer simulations. I also worked on a new sounding rocket launch system, which will allow for a reduction in cost of up to 90% compared to regular sounding rocket launch systems.